JTRF-4G Hot Melt Adhesive Granulator

Working principle:

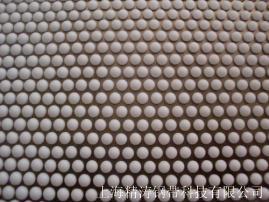

The molten material is conveyed into the granulator head at a constant speed through the material pump, and the outer drum is passed through the perforated outer drum to drop into the granular uniformly on the surface of the steel belt running below it, and then moves into the cooling area with the steel belt. The back side is continuously sprayed with cooling water, and the good heat transfer of the steel belt is used to force the material above the steel belt to be rapidly cooled and solidified during the movement process, so as to achieve the purpose of granulation and molding. Adjust the speed of the steel belt and the pelletizer head to get the most ideal pellets.

JT3000 granulator is suitable for all kinds of materials whose melting point (softening point) is within 230℃. Typical application materials are: sulfur, resin, asphalt, maleic anhydride, partial anhydride, paraffin, stearic acid products, hot melt, Various auxiliary products such as organic intermediates, compound fertilizers, rubber and plastics, etc.

Scope of application

The main advantage:

◆ Fast curing reduces the contact time with air and improves the production environment.

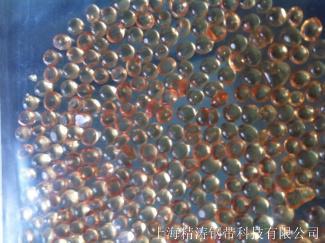

◆ The product has uniform particles and no dust, which is conducive to terminal metering.

◆ Reasonable and compact structure, easy maintenance, continuous operation and improved production efficiency.

Model specification

| Model | Strip width (mm) | Center distance (m) |

|

JT-RF-B0.6-L15 |

600 |

6.3-16.3 |

|

JT-RF-B0.8-L20 |

800 |

6.3 - 21.3 |

|

JT-RF-B1.0-L20 |

1000 |

6.3 - 21.3 |

|

JT-RF-B1.2-L25 |

1200 |

6.3 -2 6.3 |

|

JT-RF-B1.5-L35 |

1500 |

11.3-36.3 |

All rights reserved-2020 Shanghai Jingtao Steel Belt Technology Co., Ltd. 沪ICP备14044359号-1 Powered by www.300.cn

中文

中文