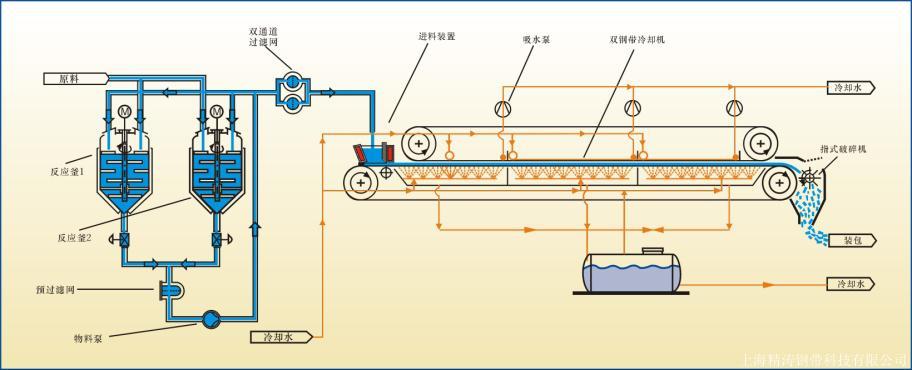

JT-DB Series Double Steel Band Sheeter

Double-strip cooling system

Scope of application:

Material Requirements: JT-DB series double belt flaker for high temperature, high melting point, high viscosity material, flash cooled and solidified resin in a typical application, the pursuit of high yield, the maximum hourly production of 10 tons.

typical application:

Resin industry, polyester resin, epoxy resin, rosin resin, ink resin, phenolic resin, etc.

The main advantage:

◆ Quick curing reduces the contact time with air and prevents material discoloration.

◆ High output, shorten production cycle

◆ Less dust, improving production environment.

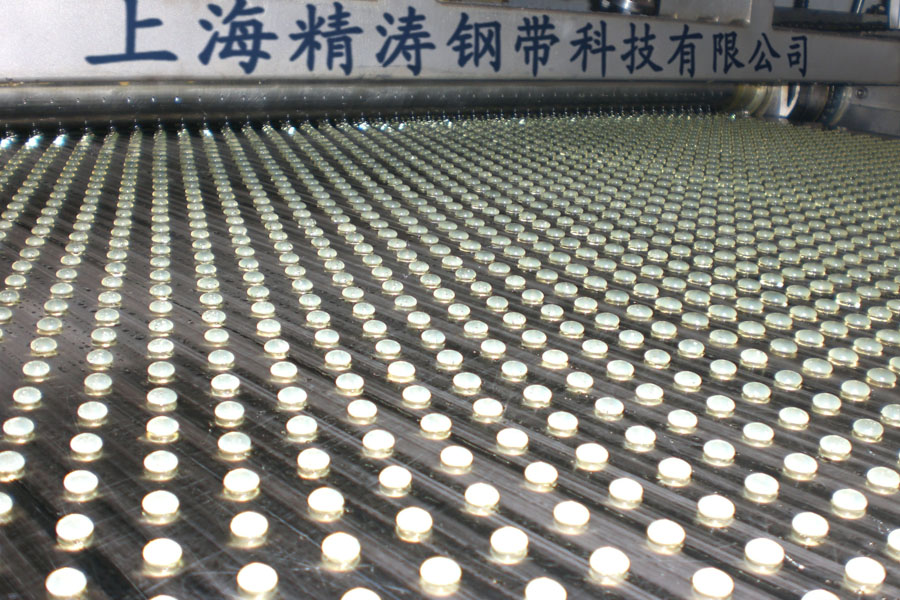

◆ The product is uniform, which is conducive to terminal measurement.

◆ Reasonable and compact structure, easy maintenance, continuous operation and improved production efficiency.

working principle:

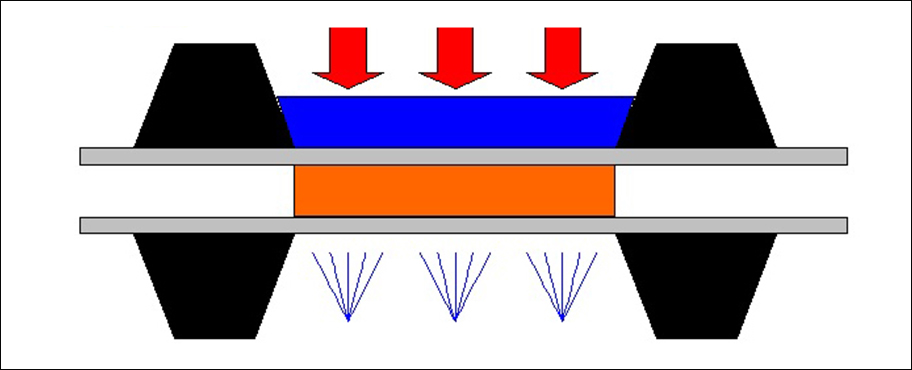

The liquid material flows through the heat mixing pipe into the distribution device (overflow trough) at the front of the equipment, and continuously overflows from the overflow trough, uninterrupted and evenly distributed between the two moving steel belts. The material is uniformly cooled by the cooling water between the upper and lower steel belts, and the excellent heat transfer characteristics of the steel belt itself make the liquid material solidify into a solid material sheet during the movement. The cured product is scraped from the steel belt by a scraper, then crushed by a crusher, and directly enters the packaging process after being collected. The sintering machine will adopt PLC centralized control, with multiple protection functions such as speed, liquid level, motor thermal protection, upstream and downstream interlocking, and a high degree of automation. Dangerous and vulnerable areas are equipped with safety protection devices, equipped with electrical safety interlock switches or emergency stop devices, with good safety performance. In the flaking machine, the cooling water does not directly contact the material, and the product will neither be contaminated nor change its composition. Because the cooling water is not polluted, it can be recycled or discharged directly, so it will not pollute the environment.

Specifications and models (can be specially designed according to site conditions)

|

model |

Strip width (mm) |

Effective cooling length (m) |

|

JT-DB1.0-L25 |

1000 |

5-25 |

|

JT-DB1.2-L25 |

1200 |

10-25 |

|

JT-DB1.5-L40 |

1500 |

10-40 |

|

JT-DB2.0-L25 |

2000 |

10-25 |

All rights reserved-2020 Shanghai Jingtao Steel Belt Technology Co., Ltd. 沪ICP备14044359号-1 Powered by www.300.cn

中文

中文