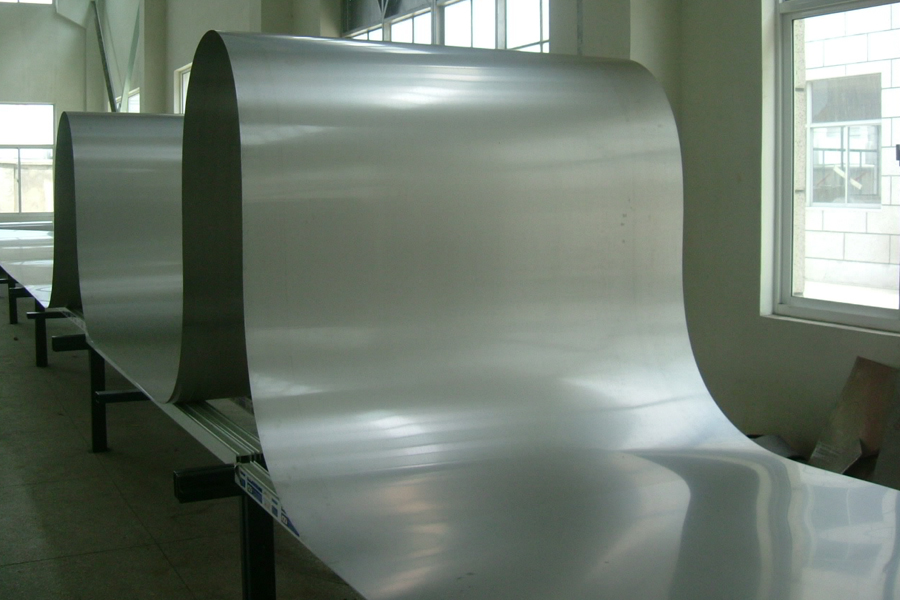

Blowing machine steel belt

Special steel belt technical requirements

Special steel strip is made by multiple deep processing on the basis of strip steel, and the production of strip steel is simply through smelting, continuous casting and hot rolling → cold rolling → trimming into strip steel coils, and its various mechanical properties None of them meet the requirements of special steel belts, and are usually used for decoration or made into workpieces for static use.

To process strip steel into steel strip, first the strip needs to undergo aging treatment, which is the most critical process in the process of strip steel production and processing. Since the strip steel will have plate-shaped waves and warping after cold rolling, and the residual stress distribution will be uneven, it needs to be stretched and straightened to relieve the stress and increase the hardness of the base metal to meet the performance requirements of the special steel strip.

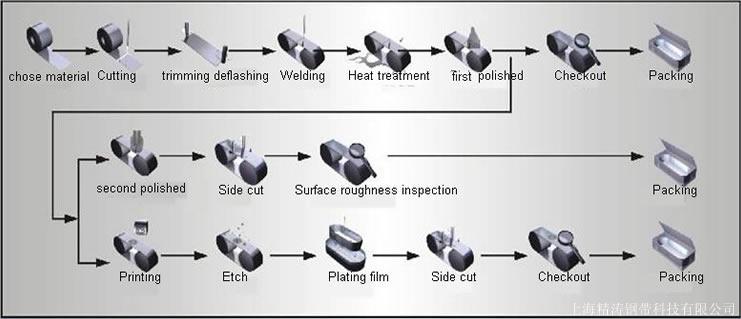

Flow chart of special steel belt processing:

JT1350SM steel belt introduction:

JT- jingtao company jingtao

1350- Tensile strength

S- stainless steel stainless

M- martensite martensite

Jingtao's high-quality steel belt has many significant advantages. JT1350SM is a precipitation-hardened stainless steel belt with superior tensile strength, good corrosion resistance and weldability.

● High wear resistance

● Fatigue and corrosion resistance

● Smooth surface and easy to clean

● Good rigidity, low elongation

● After special treatment throughout the entire circumference, all parts of the steel belt are highly uniform and have a long service life

● Resistance to cold and heat changes, adaptable to temperature

chemical composition (%)

|

C |

Si |

Mn |

Ni |

Cr |

Cu |

Nb |

|

≤0.07 |

≤1.00 |

≤1.00 |

3.00-5.00 |

15.00- 17.50 |

3.00-5.00 |

0.15-0.45 |

Mechanical behavior

|

Yield Strength |

N/mm 2 |

1100 |

|

tensile strength |

N/mm 2 |

1350 |

|

Fatigue strength |

N/mm 2 |

5 50 |

|

hardness |

HV |

380 |

|

Elongation |

% |

5 |

|

Welding factor |

0.80 |

|

|

density |

kg/m 3 |

7.78 |

|

Specific heat |

kJ/kgK |

0.12 |

|

Elasticity coefficient (200℃) RT |

N/mm 2 |

200,000 |

|

Thermal expansion coefficient (200℃) RT |

10 -6 /K |

10.8 |

|

Thermal conductivity (200℃) |

W/mk |

18 |

|

Resistivity |

μΩcm |

98 |

|

Maximum allowable working temperature |

320°C |

Applicable field

● Cooling and solidification transportation

● Heating and curing delivery

● Extrusion and transportation

● Rubber industry vulcanization transportation

● Film forming and conveying

● Composite board press

Steel strip specification (unit: mm )

<|

width thickness |

600 |

800 |

1000 |

1200 |

1500 |

2000 |

Up to 3200 |

|

0.8 |

√ |

√ |

√ |

√ |

★ |

★ |

★ |

|

1.0 |

√ |

√ |

√ |

√ |

√ |

★ |

★ |

|

1.2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

1.8 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2.0 |

★ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2.7 |

★ |

√ |

√ |

√ |

√ |

√ |

√ |

● The size of the steel belt is selected correctly, and it is determined according to the diameter of the drum, the production speed, and the use environment.

● The steel belt can be supplied with open ends and on-site welding; it can also be pre-welded into a ring field kit.

● The steel has different quality and processing precisions, which can be applied to different fields to achieve the best economic benefits.

Automatic correction system

With the continuous expansion of the use of steel belts, higher requirements are put forward for the stable operation of steel belts. According to the characteristics of steel belts and relying on years of field experience, Jingtao has successfully developed a steel automatic correction and adjustment system, which is now widely used. In various industries.

● Reasonable structure and agile movements

● High system stability,

● The adjustment range is small, and the steel belt runs more accurately

● Fully automatic adjustment, saving maintenance time

|

chemical composition (%) |

||||||||

|

C |

Si |

Mn |

Ni |

Cr |

Cu |

Nb |

||

|

≤0.07 |

≤1.00 |

≤1.00 |

3.00-5.00 |

15.00- 17.50 |

3.00-5.00 |

0.15-0.45 |

||

|

Mechanical behavior |

||||||||

|

Yield Strength |

N/mm 2 |

1100 |

||||||

|

tensile strength |

N/mm 2 |

1350 |

||||||

|

Fatigue strength |

N/mm 2 |

5 50 |

||||||

|

hardness |

HV |

380 |

||||||

|

Elongation |

% |

5 |

||||||

|

Welding factor |

0.80 |

|||||||

|

density |

kg/m 3 |

7.78 |

||||||

|

Specific heat |

kJ/kgK |

0.12 |

||||||

|

Elasticity coefficient (200℃) RT |

N/mm 2 |

200,000 |

||||||

|

Thermal expansion coefficient (200℃) RT |

10 -6 /K |

10.8 |

||||||

|

Thermal conductivity (200℃) |

W/mk |

18 |

||||||

|

Resistivity |

μΩcm |

98 |

||||||

|

Maximum allowable working temperature |

320°C |

|||||||

Applicable field

● Cooling and solidification transportation

● Heating and curing delivery

● Extrusion and transportation

● Rubber industry vulcanization transportation

● Film forming and conveying

● Composite board press

Steel strip specification (unit: mm )

|

width thickness |

600 |

800 |

1000 |

1200 |

1500 |

2000 |

Up to 3200 |

|

0.8 |

√ |

√ |

√ |

√ |

★ |

★ |

★ |

|

1.0 |

√ |

√ |

√ |

√ |

√ |

★ |

★ |

|

1.2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

1.8 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2.0 |

★ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2.7 |

★ |

√ |

√ |

√ |

√ |

√ |

√ |

● The size of the steel belt is selected correctly, and it is determined according to the diameter of the drum, the production speed, and the use environment.

● The steel belt can be supplied with open ends and on-site welding; it can also be pre-welded into a ring field kit.

● The steel has different quality and processing precisions, which can be applied to different fields to achieve the best economic benefits.

Automatic correction system

With the continuous expansion of the use of steel belts, higher requirements are put forward for the stable operation of steel belts. According to the characteristics of steel belts and relying on years of field experience, Jingtao has successfully developed a steel automatic correction and adjustment system, which is now widely used. In various industries.

● Reasonable structure and agile movements

● High system stability,

● The adjustment range is small, and the steel belt runs more accurately

● Fully automatic adjustment, saving maintenance time

All rights reserved-2020 Shanghai Jingtao Steel Belt Technology Co., Ltd. 沪ICP备14044359号-1 Powered by www.300.cn

中文

中文